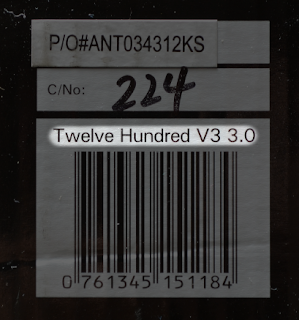

While building a Cleverbox 20 for a customer, I was surprised to find that Antec has made some slight changes to their Antec Twelve Hundred V3 chassis design. Note that neither the Antec website nor Newegg, the vendor who sold me the item, make any mention of these changes in the tech specs, photos, or in the product description. However, according to the box, the case is now known as the Antec Twelve Hundred V3 3.0:

|

| A subtle change in name |

|

| At least the photo on the box is correct… |

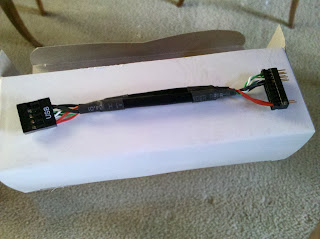

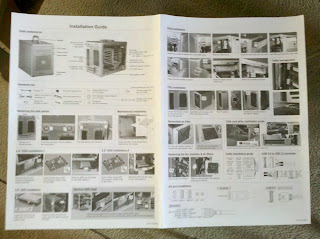

The primary change is the addition of two new front panel USB 3.0 ports, for a total of three. Secondly, they now connect directly to the motherboard with the new standard 20 pin USB 3.0 header cables:

This is a big improvement over the Antec Twelve Hundred V3, which required you to plug a long USB 3.0 cable into a rear panel port on your motherboard, which was far from elegant. My only gripe with this change is that Antec did not provide any USB 3.0 to USB 2.0 header adapters with the case. This means that if your motherboard doesn’t have any USB 3.0 headers, then you’ll need to provide your own adapters such as these from Lian Li and Corsair. A recent Lian Li case that I wrote about in a previous blog entry did come with one of these adapters. I think it would be a good practice on the part of all chassis manufacturers to follow suit. (Edit: actually, Antec may be on top of this, see below.)

The other major change is the new style of thumb screws provided:

These new thumb screws are a welcome improvement. I find them more aesthetically pleasing as they match the matte black finish on the rest of the case interior, and they are just as easy to work with. Happily, the new thumb screws can be used to secure four Norco SS-500 drive cages!

Well, sort of. They mostly fit, but you’ll find that a few of them are a bit loose or won’t tighten completely. I’m not sure if the screws or the screw holes on the drive cages are to blame. Either way, as long as you aren’t moving your server around too much then these screws should be fine to use. Antec doesn’t provide you with enough of the thumb screws to secure each cage with four on each side, but you can use just two per cage on the backside or three per cage on each side and be just fine. However, if you plan to ship your server as I will be doing with this one, then I recommend using the (expensive!) Norco screws for a tighter fit. And yes, you do still have to flatten the tabs separating the 5.25″ bays.

Protip: when installing Norco SS-500 drive cages into this case, make sure that the drive trays face down as in the photo above. This is the only way the screw holes will line up correctly. Also, adjust the depth of each cage such that the vertical pattern of two screw holes lines up, not the pattern of three.

I haven’t noticed anything else about the case that has changed. The Antec Twelve Hundred V3 3.0 is still the most economical and flexible solution for a 20 Drive tower case readily available in the US.

Edit: Just after publishing this blog post I received this email from Antec!

Trouble Ticket ID: 251059

Description: Missing USB 3.0 to USB 2.0 header adapters

Comment By: James Sean

——————————————————-

Comment: Hello Stephen,

Thank you for contacting Antec. We do have the USB3 to USB2 adapters for your case. I will contact our Parts Division on getting you these adapters out to you. You should be receiving them 7-10 business days from now.

James

Antec Support